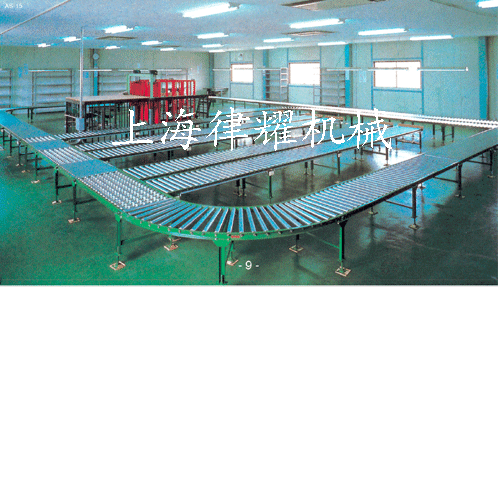

- No power roller conveyor combination

- Descritpion

Equipment characteristics

There is easy connection between the non power roller conveyor, and can be used to form a complex logistics transportation system, which can be used to realize the packing of materials. The roller conveyor is simple, reliable and easy to use.

Size specification: the width of the roller conveyor is specified by the customer, can be produced according to customer requirements, turning the radius of 3006009001200mm, etc., can also according to customer demand for other special specifications. Roller diameter of 38,50,60,76,89mm.

Optional rack material: carbon steel, stainless steel, aluminum, and other. Roller material: galvanized carbon steel, chrome plated carbon steel, carbon steel coated, stainless steel, aluminum alloy, PVC, ABS and so on.

Equipment application range

Roller conveyor is applicable to all types of boxes, package, trays and other pieces of cargo transport, bulk materials, small items or irregular items should be placed in the tray or container conveyor. Capable of transporting the weight of a large piece of material, or to bear a larger impact load. For in light industry, electronic, chemical, paper, wood, metal, mining, machinery, etc. industries.

Technical parameters

Custom no power roller conveyor please call or confirm the following technical parameters:

Length, width and height of the conveying body;

Weight of each delivery unit;

3, the bottom of the conveyor;

4, there is no special work environment requirements (such as: humidity, high temperature, chemical effects, etc.);

In order to ensure the smooth delivery of the goods, at least three of the roller and the conveyor must be kept in contact with any time points.

1, the length of the roller:

The goods should be suitable for different drum width width, typically using "delivery +50mm".

2, the wall thickness of the roller and the choice of the shaft diameter:

According to the weight of the conveying material to the contact roller, the load bearing is calculated, and the wall thickness and the shaft diameter of the roller are determined.

3, roller material and surface treatment:

According to the transportation environment, determine the materials and surface treatment of the drum (galvanized steel, stainless steel, or black plastic bag).

4, select the roller installation method:

According to the specific requirements of the overall conveyor, roller installation: spring is pressed into the type, inner tooth shaft type, the oblate tenon type through a pin hole type etc.. Bend machine for tapered roller, rolled it face width and taper depending on the size of the cargo and the turning radius and decide.